October 4, 2013

Troubleshooting Bell Problems

One of the greatest concerns of a packerhead pipe producer is bell quality. Most of the problems encountered can be avoided by following proper bell-making techniques. The following list of problems and possible causes, while not complete, should give you a good starting point towards solving your bell area concerns.

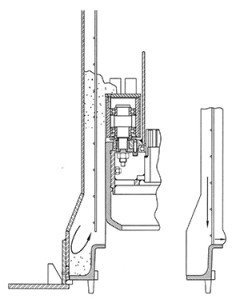

Overpack in Bell (showing cage lift)

Check these first when bell issues develop:

Overpack in Bell (showing cage lift)

Check these first when bell issues develop:

Overpack in Bell (showing cage lift)

Check these first when bell issues develop:

Overpack in Bell (showing cage lift)

Check these first when bell issues develop:

- Make sure that the bell down unit is lifting the curing pallet to the proper height.

- Check that the top of the longbottom is 1/4″ (6 mm) above the pallet when the bell down unit is raised.

- Check the timer for proper vibrating and turning time.

- Make certain that the proper amount of water is sprayed onto the concrete during the bell cycle, if applicable.

- Check that the pallets have been properly cleaned and oiled.

- Check to see that the shock absorber pads have a minimum of 1/8″ (3 mm) clearance (applies only to older machines).