July 29, 2014

Time to Upgrade Your Vision Automation

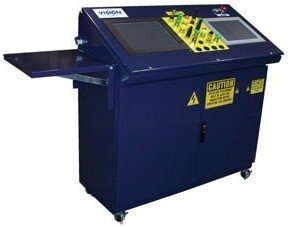

In 1993 Vision Automation revolutionized machine controls for BiDi and Packerhead pipe machines. It employed advanced electronics to provide a complete automation system that delivered the utmost control of machine operation and reliability. These controls were conveniently housed in a freestanding machine supervisor's console located on the plant floor near the pipe machine.

In 2002 we introduced Vision 2 Automation to replace the original system and in 2012 debuted an even more advanced control system. Today there are still more than 60 of the first generation Vision systems operating in the plants around the world. Unfortunately some replacement components for the original Vision system are no longer available from our supplier. We recommend upgrading your system to Vision 2 Automation now and eliminate the possibility of costly downtime due to a hardware failure.

This simple conversion replaces the original PLC, modules and the rack with a newer PLC platform. Installation can be done quickly since the new rack easily bolts to the existing panel insert and the existing terminal strips can be used with supplied adapters for straight forward wiring.

The immediate benefits of converting include the upgrade to Vision 2 programming, overall increased reliability, extended PLC program memory retention that does not require a battery, added machine program features for more precision, and compatibility with your existing operator’s touch screen.

Vision 3 Automation, the most current and standard automation system available, provides the utmost in precision and reliability for pipe manufacturing. It includes the following enhancements:

Vision 3 Automation[/caption]

Vision 3 Automation[/caption]

- Improved the video quality through the use of a 17” flat panel touch screen PC and high definition ethernet cameras. The cameras are controlled with the flat panel PC and camera software eliminating the need for separate camera controls and video switch.

- The ability to view all the cameras at once with a quadrant type view or view just one camera full screen. The cameras have the ability to pan, tilt and zoom.

- The ability to store and retrieve parts books and other documentation that may be useful on the flat panel PC.

- Additional features were added to the testing screens to aid in helping the customer with troubleshooting the machine.

- Replaced the crosshead distance encoder with a laser distance sensor thus eliminating the need to home the crosshead.

- Enhanced remote access for troubleshooting.

- Self-Cleaner Pre-Start, an optional feature, when activated starts the self-cleaner before the end of the bell cycle as determined by the end of the longest timer – turner or vibrator.

- Crosshead Lift Jog, an optional feature, when activated it runs during the bell cycle, after the bell mud feed is completed the crosshead would oscillate up and down a few inches for a user specified time.

Vision 3 Automation[/caption]

Vision 3 Automation[/caption]